1998-2018 DODGE 5.9L/6.7L CUMMINS 24V HIGH QUALITY AFTERMARKET CYLINDER HEAD STUDS 247-4202A

If you want to grab great quality head studs and you want to save a little bit of $$$, Big Dawg Diesel has got you covered!! These head studs are rated at 220,000 psi tensile strength to cylinder heads from lifting due to high combustion pressure and provide maximum durability for your Ford 6.0L Power Stroke Diesel trucks.

Fits all 1998-2018 Dodge 5.9L/6.7L Cummins Diesel

DESCRIPTION:

- 220,000 PSI TENSILE STRENGTH

- THREADS ROLLED AFTER HEAT TREATMENT

- CHROMOLY 12 POINT NUTS & PARALLEL GROUND WASHERS

- HEAVY DUTY STUDS FOR YOUR HEAVY DUTY DIESEL APPLICATION

Installation Method for Head Stud Kit

Part Number - 242-4202A Application – Dodge Cummins 5.9L 6.7L

1. Clean and inspect all hardware prior to installation. Look for obvious defects or shipping damages, plus proper fit, length and dimension.

2. To ensure proper thread engagement and accurate torque readings, clean ALL threads in the block. Use a thread chaser or thread cleaning tap

3. Install the head gasket and cylinder head

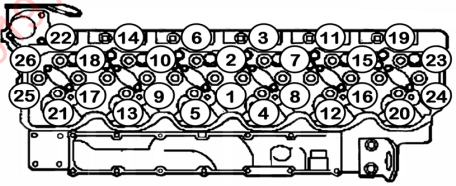

4. Screw studs into the block “Hand tight ONLY!!”. The hex broach in the end of the studs is designed to assist with installing/removing the studs from the block, not for applying torque – Note: The 6.625” long studs install along the exhaust manifold side of the cylinder head in the No. 3, 6, 11, 14, 19, and 22 position of the torque sequence

5. Lubricate both side of the washers with high quality lubricant, then place them over the studs onto the cylinder head spot faces.

6. Lubricate the stud threads and bottom of the nuts. Then install the nuts onto the thread by hand down until the nut contacts the washer.

Preload (Torque) Recommendations

7. Following the manufacturers recommended torque sequence, use a 14mm socket to torque the nuts per steps 1-3

1. Tigthen nuts 1 through 26 to 40 ft-lbs

2. Tighten nuts 1 through 26 to 80 ft-lbs

3. Tighten nuts 1 through 26 to 125 ft-lbs

TENSILE STRENGTH 234,000+ PSI - QUALITY GUARANTEED!

**⚠California Proposition 65 Warning: Diesel engine exhaust and some of its constituents are known to the State of California to cause cancer, birth defects, and other reproductive harm.

Visit: www.p65warnings.ca.gov